I’ve wanted to build a proper weld table for quite a while now. This project has gone through several iterations in my head and just about the time I’m ready to buy the materials…

I find this awesome old hydraulic lift table on Craigslist. And bam! Just like that my long considered plans are discarded, and I collect the dividends of my procrastination. A phone call and short drive later I’m thrusting a fist full of cash at the gentlemen who was delusional enough to sell such a fine piece of obtainium.

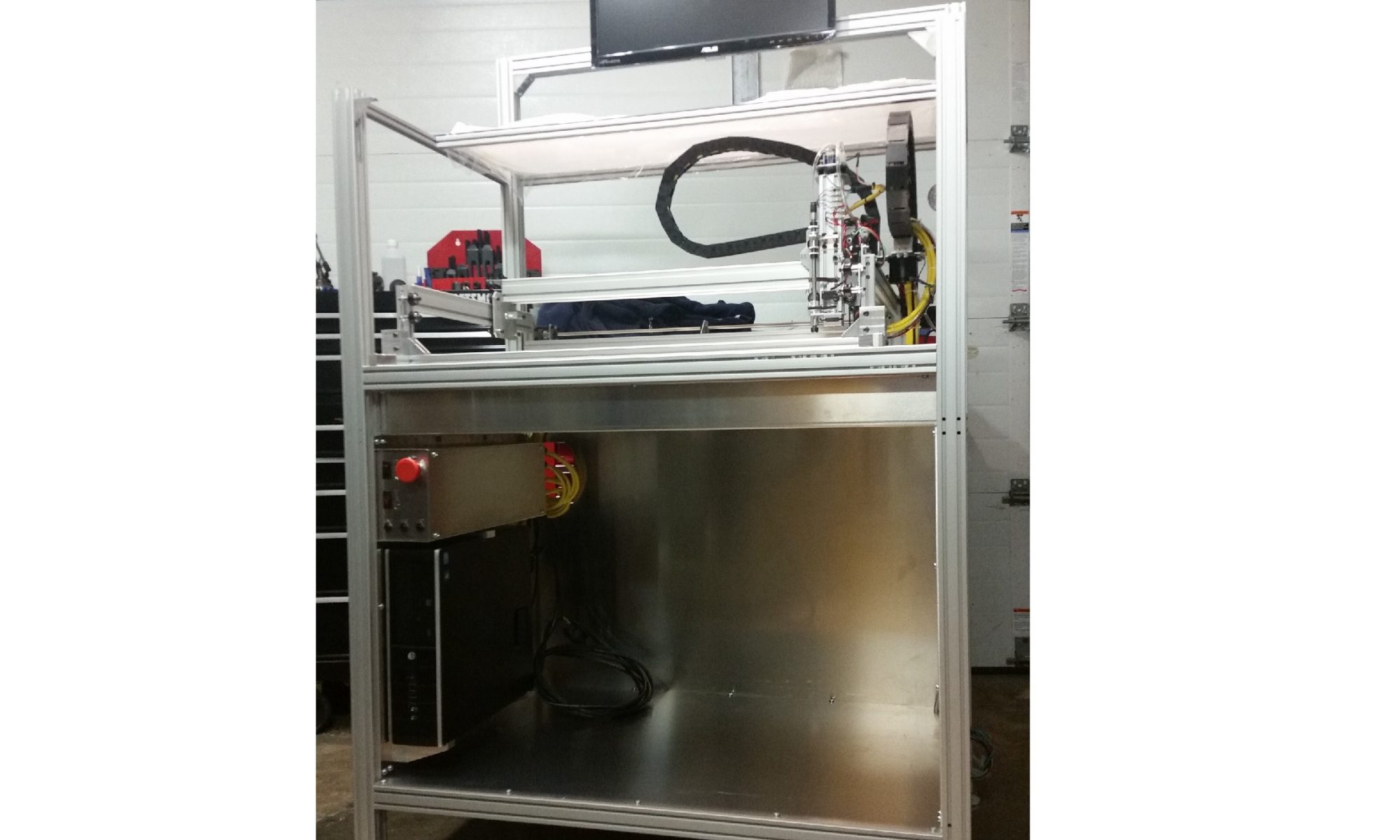

From what the seller tells me, this came from Lewis Air Force Base up in Washington state. He had purchased three of these at a government auction several years back. He included a pigtail with a rocker switch that plugs into the twist lock at one end of the table and runs the table up and down well enough. I will be adding a foot operated paddle switch in the future along with a safety “ratchet” mechanism. But for now I have some welding projects to get moving on… so this installment is to just make it functional as quickly as possible.

I had a piece of 1″ hot rolled plate hi-def plasma cut to 72″ X 36″ and hauled it home. I decided to try removing the mill scale with phosphoric acid… and it helped, but needed much more “soak time” than I (or the weather) was interested in providing. I removed most of the mill scale with a wire wheel and various stripping type wheels on an angle grinder. This left some swirl marks here and there but nothing that removed any measurable amount of metal. It’s as flat a one can expect from hot rolled and resulted in a really nice surface to work on.

The top of the lift table was about 2′ X 6′ and I wanted the 1″ plate work surface to extend beyond the supporting structure on all sides to allow for easy clamping, so I trimmed down the ends of the lift table.

I wanted to create a little bit of space between the bottom of the 1″ steel plate and the top of the lift table, so I built these riser mounts. This makes a convenient shelf space for vise grips, sharpies, tape measures and all the other small things that are nice to have close at hand for welding and fab work.

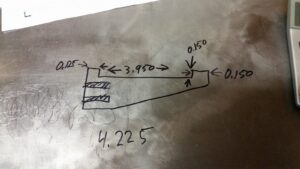

Next up was drilling and countersinking the 6 mounting holes in the work surface. I carefully measured & scribed my hole pattern, then center drilled, through drilled, and countersunk the holes. The 1/2″-13 flat heads sit just a hair below the surface of the steel plate.

I bolted the riser mounts to the bottom of the plate, lined the lift table up underneath, and picked er up. After tacking the mounts to the lift table I unbolted the plate and set it back on the jack stands. I welded out all six mounts then reinstalled the plate.

I’m really happy with how this turned out, especially considering how little effort it required to bring together. The hydraulic lift table was a really lucky find and eliminated a ton of work. I was originally planning a fixed height welding table on casters… this is sooo much nicer and was far less work.

The 1″ plate is stiff enough to allow for the large overhang on all sides. This makes it really nice to clamp parts in place for welding. As you can see there is plenty of room on the end to accommodate the full depth of the deep throat Vise Grips.

When lowered all the way, the work surface sits about 11″ off the floor, and raised all the way sits right at 48″. This is a real back saver when getting heavy things on and off the table. It’s also super nice for the small fiddly stuff because I can raise it way up and don’t need to be hunched over. Additionally it’s been useful for getting heavy stuff in and out of truck beds, reaching things on high shelves, amusing small children… don’t try this at home… seriously people… I’m not Mr safety… not even close… you’ve been warned!

As I mentioned earlier, I will probably revisit this later to refine some of the details. I plan to add a safety ratchet mechanism and a foot operated switch to raise and lower. For now I really appreciate having a flat & true surface to weld on. It’s also super nice to be able to ground through the table and not have a ground clamp constantly in the way.